Customer Hot Line:

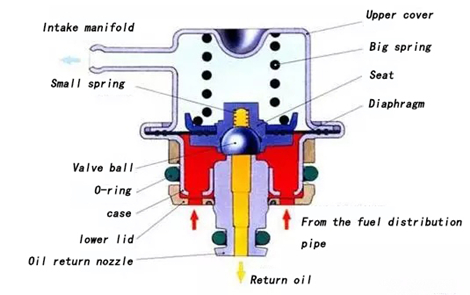

+86 15622179651In our world, there are hundreds of diesel engine manufacturers, each brand of diesel engine fuel, its fuel injection system is not only two kinds, one is mechanical fuel injection system, the other is electronically controlled fuel High pressure common rail injection system. The mechanical fuel injection system uses a traditional mechanical fuel pump, which is driven by a camshaft. The pressure of the fuel injection increases with the increase of engine speed and fuel injection. The diesel system has unstable atomization effect and cold start. Difficulties and other issues, but also unable to meet the increasingly stringent emission standards and the desire to reduce fuel consumption. Electronically controlled diesel high pressure common rail system. It has a higher injection pressure, better atomization, lower fuel consumption and cleaner emissions.

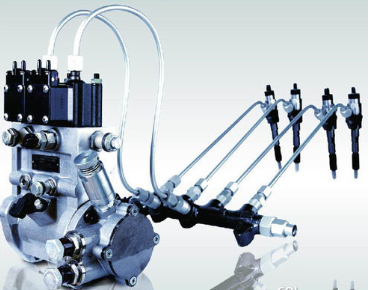

The function of the high pressure pump is to compress the fuel from a low pressure state through a plunger to a high pressure state to meet the fuel injection pressure and fuel injection requirements of the system and the engine.

Release time:2019-07-15 Text source:Guangzhou Ruixiao Trading Co.,

What is a Common fuel pump? The Common fuel pump is known as the heart of the diesel engine. Is the most important component of the diesel fuel supply system Is to provide high pressure diesel fuel injectors regularly and quantitatively. Wh...

Release time:2019-03-04 Text source:Guangzhou Ruixiao Trading Co.,

I have recently seen many friends asking me about engine jitter and poor acceleration, and some even dont know how to check fuel pressure. Today, we will tell you about the fuel system, how to measure the oil pressure, and some troubles tha...

Release time:2018-10-03 Text source:Guangzhou Ruixiao Trading Co.,

Mechanical fuel pump Diagnostics Using Scan Tools Most common Mechanical fuel pump diagnostic procedures in the past could be performed with a pressure gauge and a volt meter. the most important tool is the scan tool. On early import vehicl...

Release time:2018-09-30 Text source:Guangzhou Ruixiao Trading Co.,

How to Replace the Injection Pump in a Gas Tank If your gas tank is full but your engine isnt getting any gas, you may need to substitute the injection pump. However, first make sure the problem isnt a broken gas line, clogged filter or an...

Release time:2018-09-17 Text source:Guangzhou Ruixiao Trading Co.,

How to Buy a High performance fuel injectors The high performance fuel injector, injects fuel into the engine at the right time to ensure optimal efficiency. Older automobiles had carburetors that mixed the air and fuel before delivering it...