Customer Hot Line:

+86 15622179651Your current position:home > Diesel injection news

In 2000, ruixiao became a member of the China Automotive Diesel Engine Parts Sales Consortium.

Release time:2019-06-23 Text source:Guangzhou Ruixiao Trading Co.,

When the diesel generator set is in use, it may be automatically turned off ......

Release time:2019-06-10 Text source:Guangzhou Ruixiao Trading Co.,

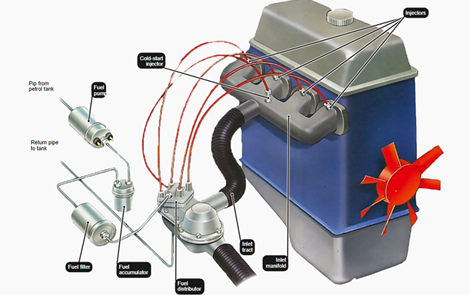

For the engine to run smoothly and efficiently it needs to be......

Release time:2019-04-17 Text source:Guangzhou Ruixiao Trading Co.,

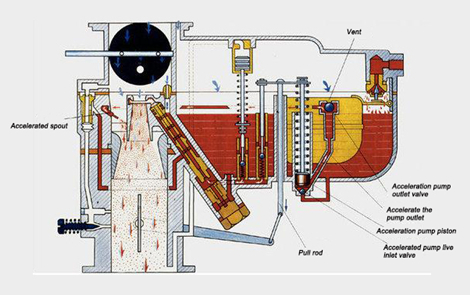

Why does the bus and truck emit black smoke? 1: The oil supply of .......

Release time:2019-04-12 Text source:Guangzhou Ruixiao Trading Co.,

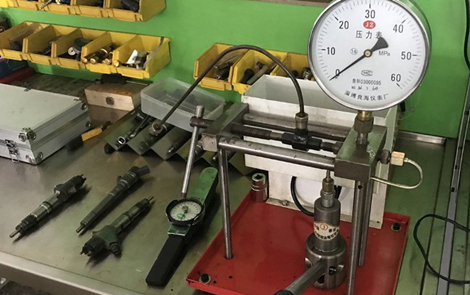

Why are there fewer cleaner injectors now, are they not cleaned, and how ......

Release time:2019-03-31 Text source:Guangzhou Ruixiao Trading Co.,

The maintenance of the injector is a precise and technically demanding......